Wander down the aisle of your local hardware store and you will discover a massive variety of hammers available. They vary in shape, size, weight, and styles, and have a myriad of uses. Have you ever wondered where this most useful tool came from, and what exactly it is capable of? This article delves into surprisingly fascinating world of all the different kinds of hammers and their usages.

History of Hammers

The origin of the first hammer has been lost to pre-history. It would have most likely begun as a simple rock, which would have eventually been connected to a stick, bone, or antler with some sinew, in order to maximise its striking power.

However, it was not until the Roman Empire, in the first century, that we find the emergence of a dual-function hammer that could both pound in and pry out nails – the precursor to everyone’s favourite tool, the claw hammer!

FUN FACT: You may occasionally see nail sizes such as 4d, 6d, 8d etc. (particularly if you live in the USA). This is in fact a legacy of the Romans, who made extensive use of nails for construction. The “d” stands for the Roman coin ‘denarius’, which was also the name for an English penny during Roman occupation. Fast forward to 15th Century England, when each nail was hand-forged, one at a time. It is believed that a hundred 3-1/2 inch nails would have cost 16 pennies and thus became known as 16-penny nails, or 16d.

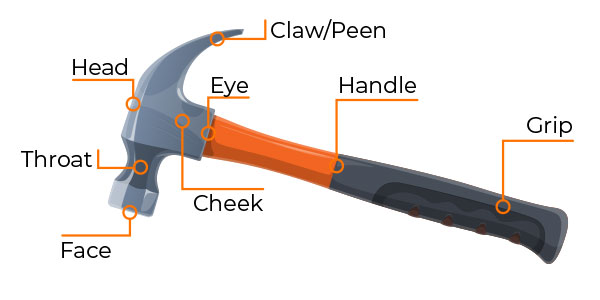

Anatomy of a Hammer

Surprisingly, the shape of hammers has not altered a great deal from the Roman design, although some modern materials are now used in both the head and handle.

Traditionally, handles were made of wood fixed through a hole in the head, which allowed the handle to be easily replaced if needed.

Modern hammers use materials and the handles that are often built into the head, sometimes with a form of built-in shock absorber to make them easier to use.

Over the centuries, hammers have evolved to suit different needs and materials. From hammering nails, demolishing walls, and panel-beating Rolls, to everything in between. The humble hammer has pounded, tapped, shaped and formed its way into history.

Different types of Hammers

Claw Hammer

The most popular hammer for general work, available with a wooden (often hickory), glass-fibre or steel handle. Primarily used to hammer in nails. The claw is normally curved, and has a 'V' cut-out to extract nails from wood. Additionally, the claw can be used to lever objects.

Find Claw Hammers here.

Ball Pein/Peen

Normally used by engineers, the pein (or peen) is rounded and used for shaping metal and closing rivets. It gets its name from a fabrication method called “peening”, which is used to help a weld joint stretch as it cools.

Find Ball Pein/Peen Hammers here.

Cross Pein/Peen

Primarily used for shaping metal, the hammer has a regular-shaped hammer head and one that is wedge-shaped. It can also be used for starting panel pins and tacks. Handles are normally wood, usually Ash.

Find Cross Pein/Peen Hammers here.

Club Hammer

This double-faced basher is useful for light demolition work, as well as driving steel chisels and masonry nails. With a weight of around 1135g (2 1/2 lb), it is perfectly suited to domestic work. Handles are normally wood, usually Hickory, or synthetic resin. We recommend safety glasses and working gloves, because debris is likely to fly.

Find Club Hammers here.

Sledge Hammer

If you want to break something, this beast is for you! Used for the heavier jobs, such as driving in stakes or to break up concrete, stone or masonry. These sturdy tools weigh around 7 to 14lb. When using, wear suitable protective clothing, including safety glasses.

Find Sledge Hammers here.

Dead Blow Hammer

A specialized mallet designed to deliver enough force to dislodge parts and fix dents without damaging the workpiece, and with minimal rebound. The dead blow hammer is usually made of rubber or resilient plastic. They are used mostly in woodworking and automotive applications.

Find Dead Blow Hammers here.

Joiner's / Wooden Mallet

The Joiner's Mallet is a traditional tool is used to drive chisels or to tap wood joints together, where a metal-faced hammer would cause damage. Note that the head is slightly tapered to ensure correct contact with the work. Both the handle and head are wood, quite often Beech.

Find Wooden Mallets here.

Rubber Mallet

A lightweight tool with a head made of moulded rubber or hard plastic and a wooden or fiberglass handle. They are useful for when a steel face would cause damage, such as pavers, forming sheet metal or snugging up joints in PVC pipe.

Find Rubber Mallets here.

Welder's Chipping Hammer

Used for cleaning and removing slag after arc welding, and also for boiler scaling applications. The all-steel construction makes it both solid and strong. The chipping hammer features a striking head with a sharp conical point and a flat chisel bevelled end. The unique helical barrel spring handle helps to prevent kickback, and reduce resonance. This helps to avoid fatigue during long periods of use. It also has a special ability to dissipate heat.

Find Welder's Chipping Hammer here.

Tips for using hammers

1. Always use the right hammer for each job. The correct tool will make jobs easier and avoid possible damage to both the tool and workpiece.

2. For delicate work, use a piece of scrap wood between the work piece and the hammer, thereby preventing damage to the workpiece.

3. Use a nail punch to sink nails into the timber, again preventing damage to the workpiece. A nail punch has a flat end, which fits the nail head rather than a pointed end that other punches have.

4. Regularly check that the steel wedges are tight. Be aware that timber handles can shrink in dry conditions.

5. If a timber handle does loosen, place the head in water overnight. Water will cause the handle to expand and tighten the head in.

6. If a hammer tends to slip off nails, roughen the face of the head using a medium abrasive paper.

7. Always wear safety glasses, especially when driving masonry nails or breaking up concrete.